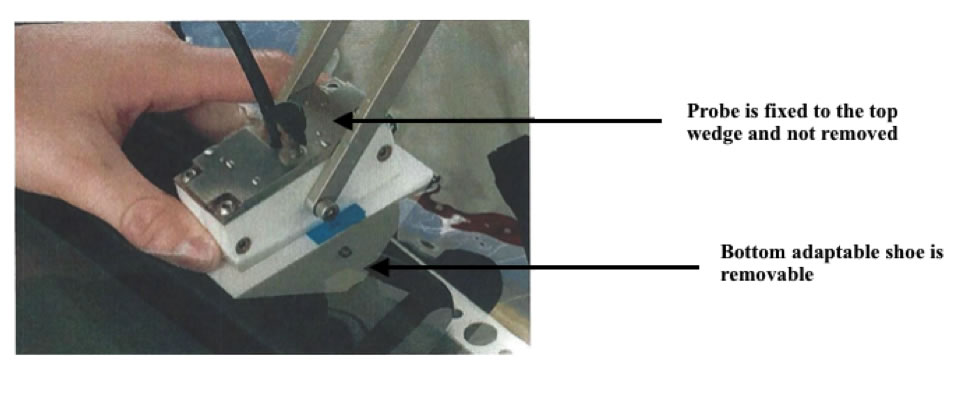

Manual Scanners

X-Y Scanner

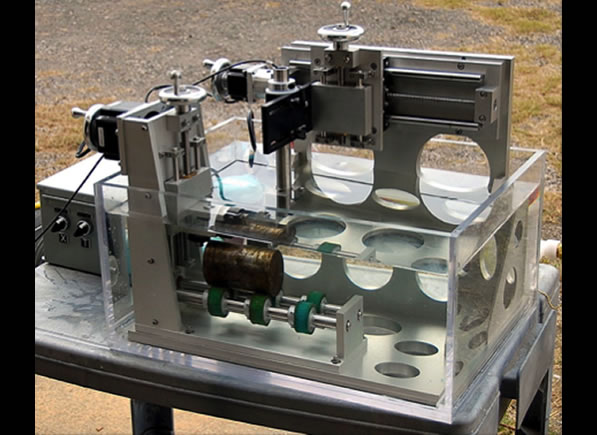

Laboratory Tank

Custom Scanner

Semi-Automated System

- Semi-Automated for Composite inspection

- M2M or ONDT electronic

- Support table

- Immersion tank

- 3 axes scanner

3D Composite System

- 5 axes immersion scanner

- Automatic scan plan generation

- 3 D contour following

- Option robot to handle parts

- Vision system to identify and recognize parts

- One part every 2 to 3 min

- Automated Analysis

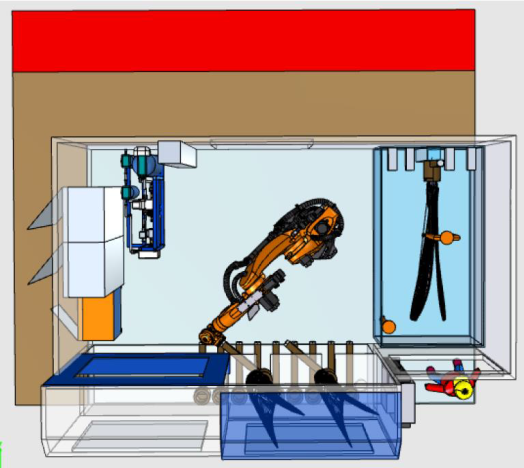

Automated Ultrasonic Blade Inspection

TD NDE offers a turn-key automated system for blade inspection.

An immersion tank is installed near a 6 axis robot. The robot is responsible to move the blades from their rack into the tank and to follow a scan path using different type of transducers and holders.

The inspection system is designed to inspect composite blades for defects and titanium. It inspects disbounding, delamination, foreign material and crushed core/foam/honeycomb.

The system comes with all the necessary hardware and software and includes delivery, training and support. It’s fully automated from inspection to part evaluation.

Mepuls

- Fully automated thickness measurements

- Wireless

- Integrated to CNC

- High accuracy +/- 0.0001”

- Use cutting fluid

- IP 68

-White.png)