Alignment with BestFit/VolumeFit

- Adaptive Technology

OpenFIT

During the manufacture of new parts as well as during repairs, problems frequently occur during the exact alignment of parts. These problems are caused by production-related part deviations, simple fixtures or differences in their handling:

- Nevertheless, machining of the part must take place in the planned position.

- It is important to take account of overmeasures when reworking cast or printed rough parts so that the final geometry will “fit” into the cast rough part.

The software packages BestFit and VolumeFit are suitable for solving problems of this kind and carrying out similar tasks. Both systems capture the position of the parts inside the machine by using a built-in measurement module for tactile measurements or by importing appropriate data from other systems.

BestFit adapts the position and orientation of a planned machining sequence in a way that minimizes deviations.

VolumeFit also takes account of overmeasures at the machining location. This ensures that appropriate overmeasures are available on all surfaces to be machined. Both methods adapt NC programs previously generated by the customer with CAM systems.

Your Advantages:

- A complicated manual alignment process is no longer necessary.

- The requirements for the fixture are reduced, thereby lowering costs.

- You have control over the machining overmeasure (VolumeFit).

- The program can be easily integrated into the present process workflow.

Applications

Compensation of clamping mistakes

Serial parts clamped in a simple fixture exhibit differences in orientation. The position of the part is measured. The NC programs are either adapted directly or implemented in unchanged (!) form within a new coordinate system on the machine.

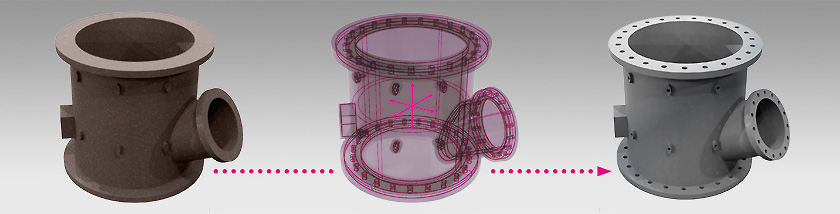

Reworking of 3D printed parts

Drillings, fits and functional surfaces are created, after the actual printing, via classical manufacturing methods such as milling or drilling. To achieve the correct orientation during machining procedures, the position of the part inside the NC machine is measured. To increase accuracy, the compensation also takes account of the degree of freedom of the fixture.

Reworking cast parts

On larger cast parts, flanges etc. are to be machined. For this purpose, the position of the part as well as the local overmeasure at the machining points is taken into account. The information on position and overmeasures is obtained either by direct measurement in the machine or via the import of measurement data from external sources.

-White.png)